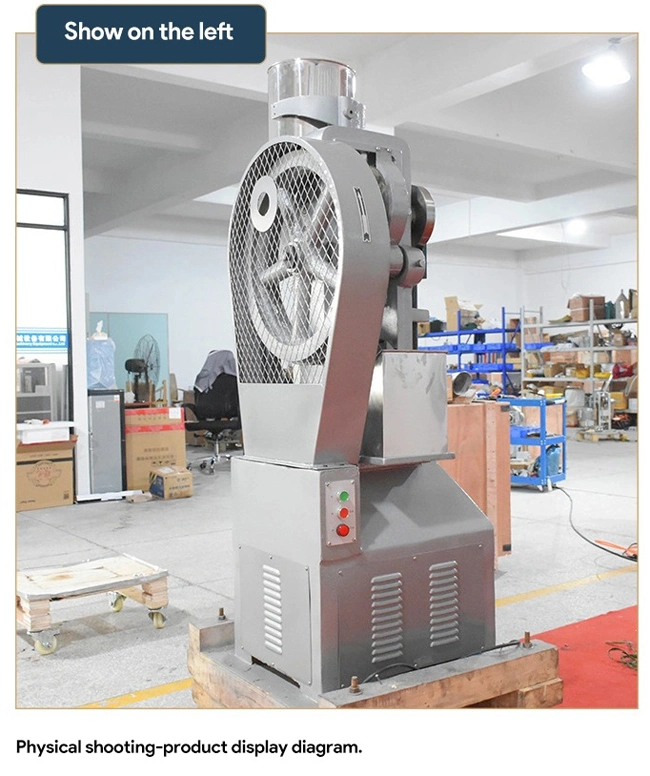

Automatic Flower Basket Tablet Press Machine for Big Tablet, Powder Molding Machine, Compaction Machinery For Tablet Press

Product Details:

| Production Capacity | 25pcs/min(the actual speed according to product process requirement) |

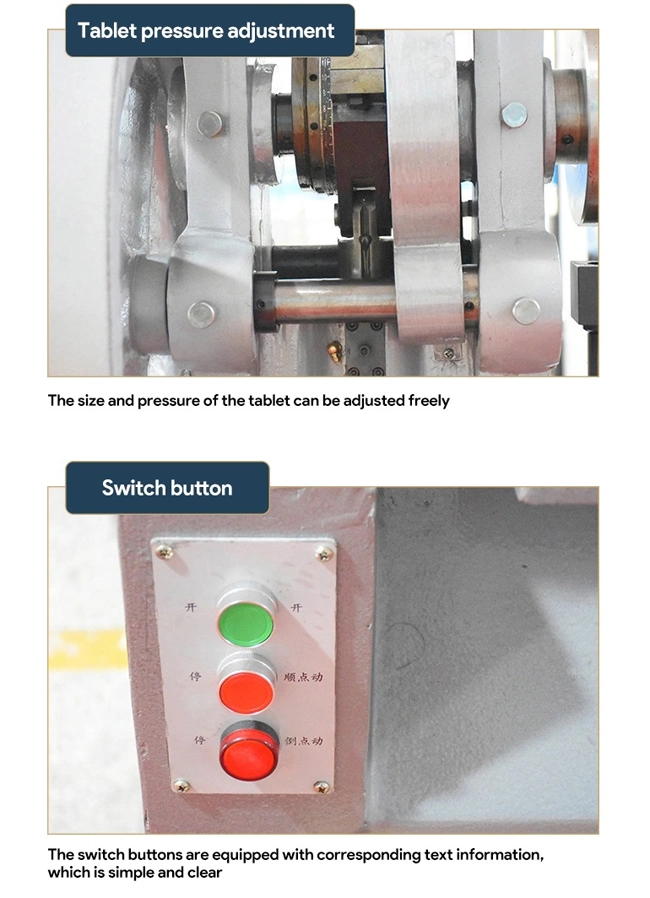

| Working Pressure | ≤20T(1.step-less adjustment 2.can be bidirectional compress) |

| Working Stroke | Up stroke≤150mm,Down strokes≤100mm(1.step-less adjustment 2.Customized based on customer's request.) |

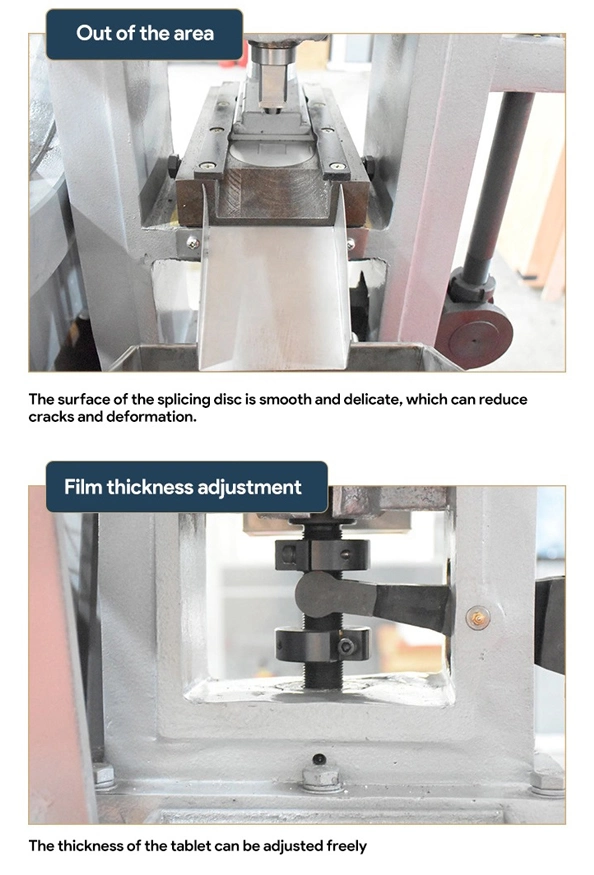

| Filling Depth | ≤60mm(1.step-less adjustment 2.Customized based on customer's request.) |

| Product Mould | Customized according to the tablet features(Multi-cavity Mould) |

| Tablet Diameter | ≤120mm |

| Apply to Shape | Round,square,or special-shaped(suitable for a variety of shapes) |

| Motor Power | 4kw(Servo) |

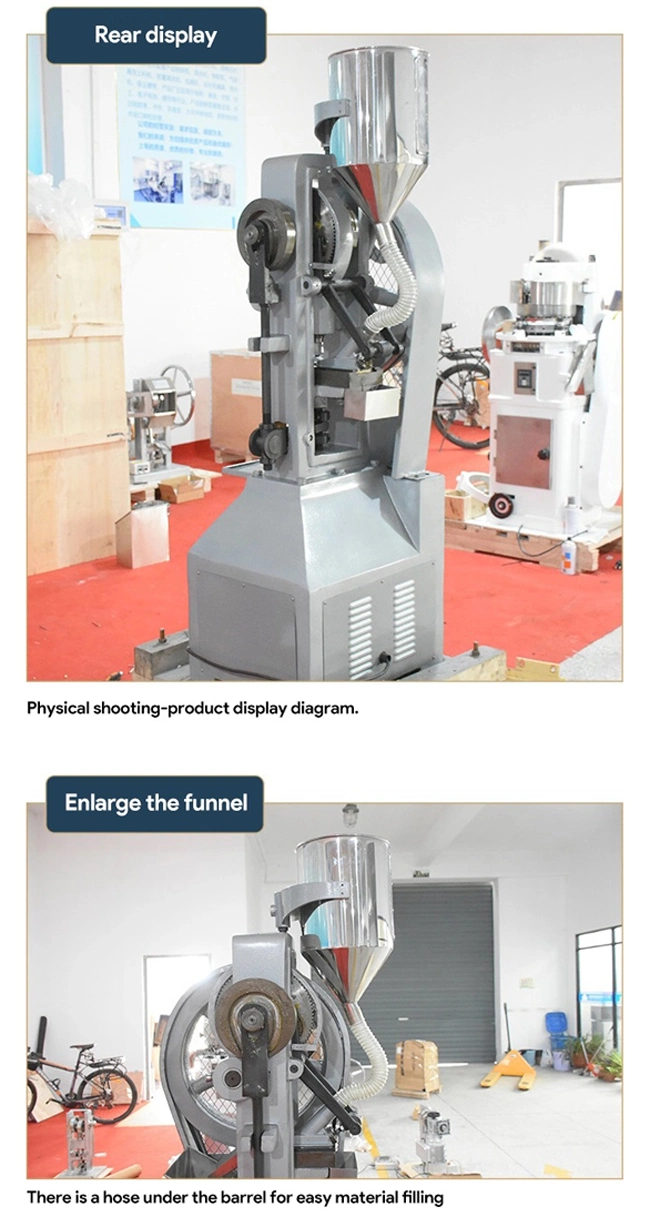

| Weight&Size | Approximately:1000kg,780mm*600mm*1900mm(L*W*H) |

This tablet press machine is a continuous automatic tablet press which is one of the essential equipment for pressing granular raw materials into tablets or medicines taken with water in pharmaceutical, chemical, food, electronics industries.

Our tablet press machine can be used to press medicinal tablets, catalysts, candies, calcium coffee pills, powder metallurgical parts electronics components, various tablets of pesticide and fertilizer etc. in small-batch production, laboratory and hospital.

This tablet press machine can press special-shaped, ringlike tablets of different kinds, and can also process the tablets of pesticide both sides are impressed trademarks, letters and simple patterns.

Descriptions and Advantage:

1.Fully CNC Control DesignEach action can be set separately. Special material tablet forming can be solved by precise control and flexible technology.

2. Fully Intelligent Operation DesignProduction debugging is operated through PLC touch screen, which can cut the cumbersome process in great scope and make the operation more easily.

3.Fully-automatic Material Filling DesignThe filling method and dosage can be intelligently controlled, rapidly and stably, which can save much time and labor.

4.Isolated Hydraulic Station DesignOil cylinder working area and mechanical working area are Mutual independence, preventing oil pollution.

5.Reasonable Structure Design- energy saving and environmental protection

- small space occupation

- superior performance

- simple operation

- easy maintenance and so on.

Using Guides

1. Frequently check the quality of the tablet during use. If there is the raw edge, wale and uneven thickness, check the die in time. Do not use the nonconforming products lest the machine is damaged.

2. Do not use the wet materials in order to avoid destroying machine.

3. In case of tablet skipping, stagnation and other failures, do not touch with hand to avoid injury.

4. When refilling the oil, do not make the oil overflow or even drop on the surface of the working bench or around the die lest the quality of tablets is affected.

5. When switching on power supply, make sure the flay wheel rotation direction is the same as the indicated. Do not run in reverse direction to prevent damage to the parts.

Technology and Advantage:

Protecting the compressed tablet well,which are damaged by improper mould forces in the course of production.

2.Uniform Density

Uniform density of the compressed tablet can be ensured through special technology.

3.Different layer different color

Can compress the tablet with different layers and different colors.

4.Multiple Production Capacity

Production capacity can be raised many times under certain conditions.

5.Safety Protection

If some abnormal condition occurs,it will stop immediately and minimize its negative effects.

Applications

| Agriculture: | Feed block, fertilizer tablets, animal food, animal salt lick |

| Electronics Batteries: | Thermistor, integrated circuit components, carboniferous brush films... |

| Health Products: | calcium, propolis tablets, effervescent tablets, bath salts tablets... |

| Chemical: | disinfection tablets, insect repellent films, camphor ball, detergents, fragrances, catalysts, metallurgy powder, glass powder, ceramic powder products, art powder, sand round block, magnetic materials... |

Before-sale Service

1. Professional consultation about each type of machine is provided.

2. Free testing service is offered to help customers purchase suitable machine.

3. Warm welcome to visit and evaluate our factory.

4. To press heavy block like animal salt block, licks, we need larger pressure, below rules are for your reference:

A. We would like to recommend machines based on your requirements as following:

1. Product name

2. Products' size and shape

3. Products' weight

4. Capacity

B. We will design, customize and make dies for you.

After-sale Service

1. All the machines will be adjusted and tested before shipping.

2. Installing,debugging and training to workers are all offered, after customers receiving our tablet press machine.