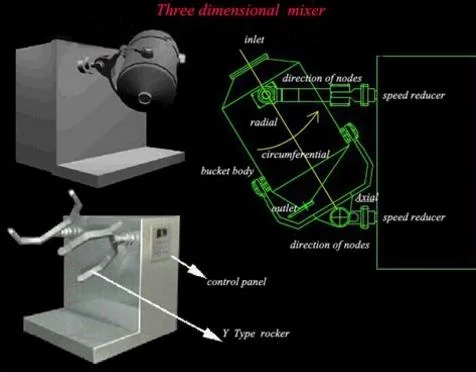

laboratory trial production dry powder mixing equipment (three-dimensional mixer machine)

We will send you offer if you can provide us below information:

----What materials do you mix? (Names of raw materials?)

----What is the powder fineness/particle size? (how much mesh, mm, micro?)

----What is the bulk density/specific gravity of mixed materials? (how much kg/m3, g/cc?)

----How many kgs to be mixed per batch?

1, Working principle:

Different with traditional rotary mixer on working principle, three-dimensional mixer make horizontal movement, rotation, swinging in the cubic three-dimensional space. Materials are in combined motion of rotary flowing, horizontal moving, upside down falling; alternating pulses push materials continuously; turbulence caused by the combined motion has energy gradient and this make each particle of mixed materials have different motion state; each particle of mixture change their own position; and thus the materials get mixed homogeneously.

2, Technical specifications:

Performance & features:

01 Material: stainless steel 304 / 316L (special materials like wear-resistant, anti-corrosion materials available);

02 Surface treatments: polish/sandblasting (special treatment like wear-resistant, anti-corrosion treatment available);

03 Mixer tank: cylinder;

04 Mixing time: 5-20 minutes (depends on different material features & production requirement);

05 Working model: batch mixing;

06 Speed reducer;

07 Rotation speed: fixed speed (changeable speed available);

08 Openings on top: feeding inlet, manhole (can be customized);

09 Discharge valve: manual butterfly valve (can be customized);

10 Working condition: normal pressure and temperature (pressure & temperature requirement available);

11 Power supply: 220V 50HZ single phase/ 380V 50HZ 3 phase (can be customized);

12 Non ex-proof motor, electronic elements, control cabinet (ex-proof requirement available);

13 Other customized features: to be confirmed;

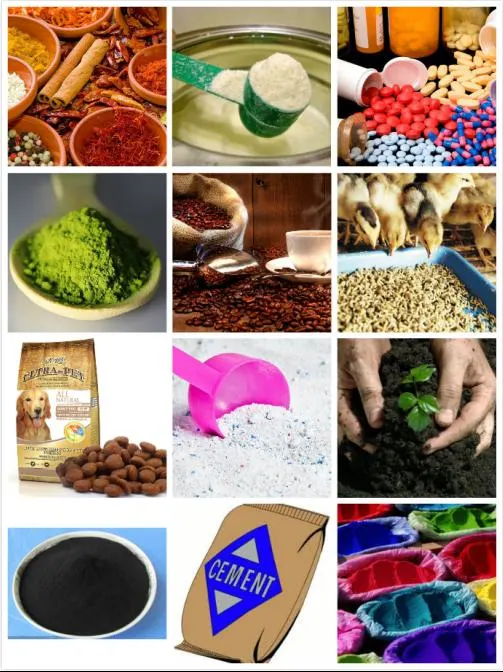

Application industries:

6 Our Factory:

We will send you offer if you can provide us below information:

----What materials do you mix? (Names of raw materials?)

----What is the powder fineness/particle size? (how much mesh, mm, micro?)

----What is the bulk density/specific gravity of mixed materials? (how much kg/m3, g/cc?)

----How many kgs to be mixed per batch?

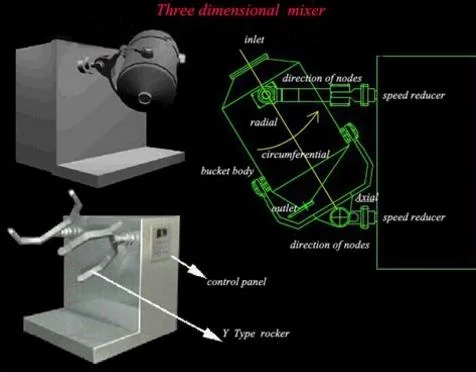

1, Working principle:

Different with traditional rotary mixer on working principle, three-dimensional mixer make horizontal movement, rotation, swinging in the cubic three-dimensional space. Materials are in combined motion of rotary flowing, horizontal moving, upside down falling; alternating pulses push materials continuously; turbulence caused by the combined motion has energy gradient and this make each particle of mixed materials have different motion state; each particle of mixture change their own position; and thus the materials get mixed homogeneously.

2, Technical specifications:

| Specs Model | Working capacity (L) | Working capacity (kg) | Speed (r/min) | Power (kw) | Dimension (mm) | Weight (kg) |

| CMP3-5 | 4.5 | 1.5-2.7 | 0-20 | 0.25 | 600 ×1000×1000 | 100 |

| CMP3-15 | 13.5 | 4-8.1 | 0-20 | 0.37 | 800 ×1200×1000 | 200 |

| CMP3-50 | 45 | 15-27 | 0-20 | 1.1 | 1150 ×1400×1000 | 300 |

| CMP3-100 | 90 | 30-54 | 0-20 | 1.5 | 1250 ×1800×1550 | 800 |

| CMP3-200 | 180 | 50-108 | 0-15 | 2.5 | 1450 ×2000×1550 | 1200 |

Performance & features:

01 Material: stainless steel 304 / 316L (special materials like wear-resistant, anti-corrosion materials available);

02 Surface treatments: polish/sandblasting (special treatment like wear-resistant, anti-corrosion treatment available);

03 Mixer tank: cylinder;

04 Mixing time: 5-20 minutes (depends on different material features & production requirement);

05 Working model: batch mixing;

06 Speed reducer;

07 Rotation speed: fixed speed (changeable speed available);

08 Openings on top: feeding inlet, manhole (can be customized);

09 Discharge valve: manual butterfly valve (can be customized);

10 Working condition: normal pressure and temperature (pressure & temperature requirement available);

11 Power supply: 220V 50HZ single phase/ 380V 50HZ 3 phase (can be customized);

12 Non ex-proof motor, electronic elements, control cabinet (ex-proof requirement available);

13 Other customized features: to be confirmed;

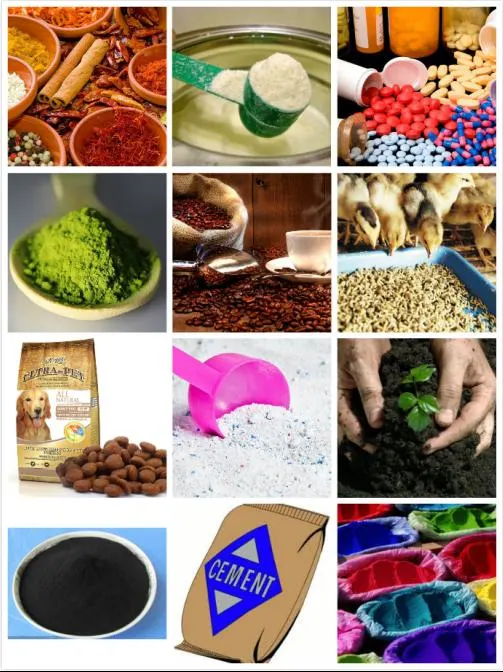

Application industries:

6 Our Factory: