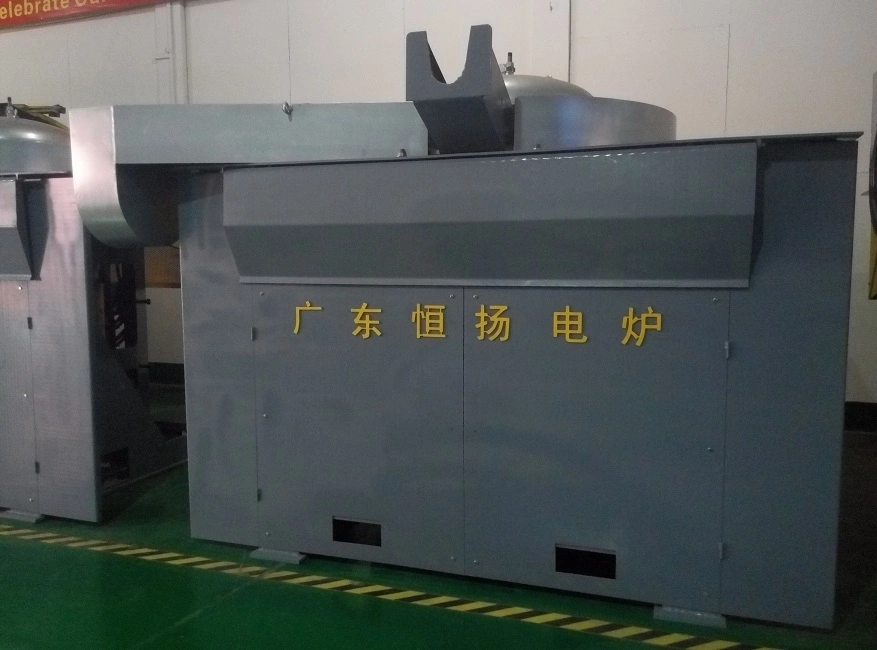

1.5 ton capacity steel shell furnace with dust ring

Application: It can melt all kind of steel for casting mill balls, rebar, ingot and other casting product.Melting material: carbon steel, stainless steel, high chrome steel , high manganese steel, wild steel ect.

Melting rate:at least 1.5 tons per hour and temperatures of 1650°C being achieved.

Major Unite

1) steel shell furnace body

2) Hydraulic station and tilting control device

Details description:

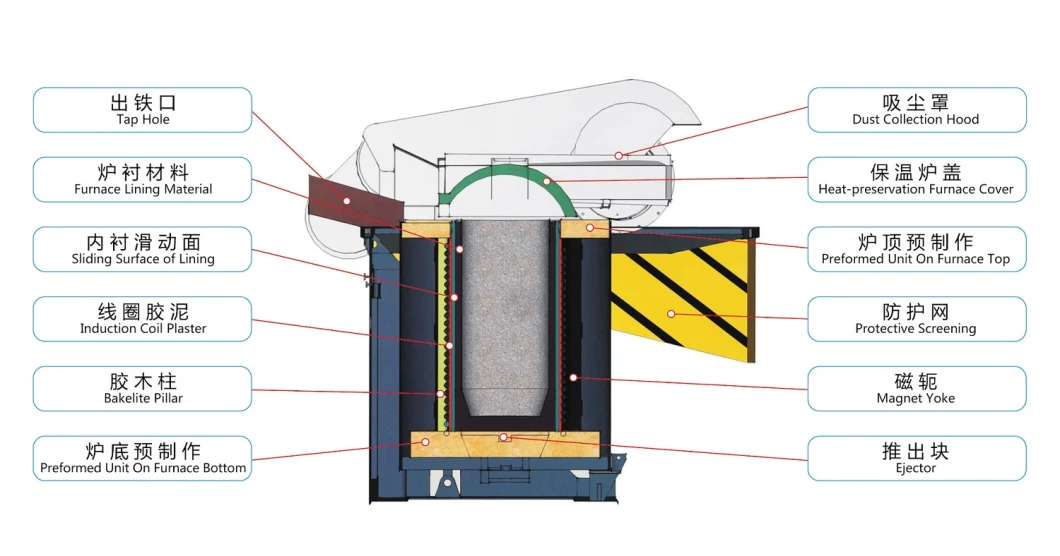

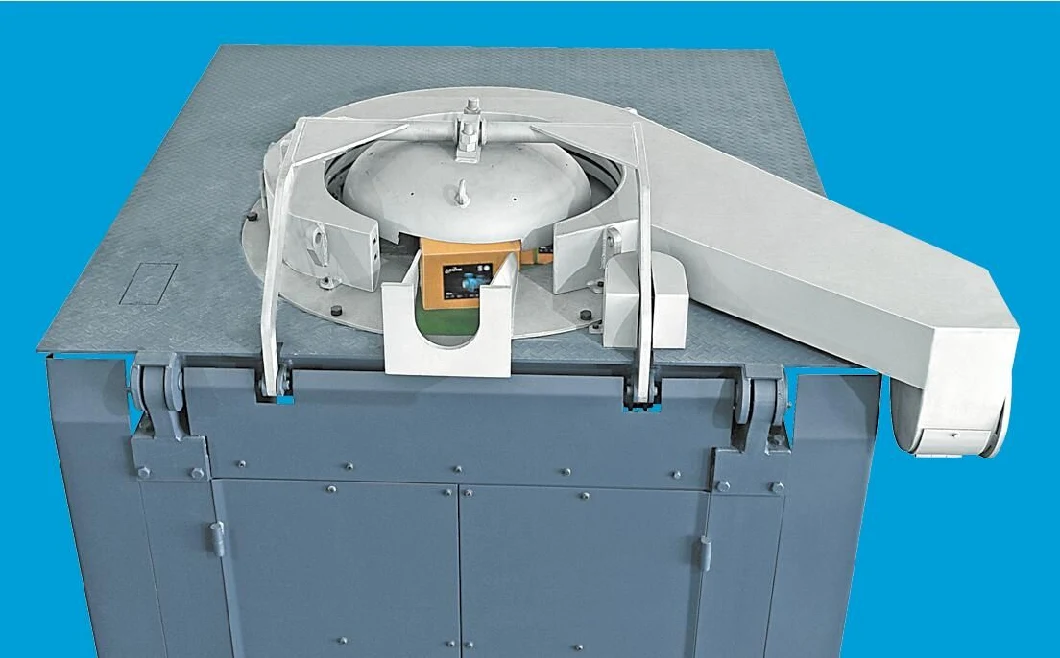

- Open furnace structure. The basic structure: with unique shock absorber and solid magnetic yoke, two cylinder with thick wall seamless rectangular steel tube is welded into one structure, being safer, firm, durable, high efficient. The upper end of the induction furnace can be disassembled to facilitate the replacement of the coil.

- Dust ring & Furnace cover. Dust ring can absorb dust and exhaust gas generated during melting process through air. When working with dust removal system, they can reduce the exhausted gas emission, to meet the environmental requirements. It is suitable for semi-automatic or manual feeding and discharging production line in which dust hood cannot be used.

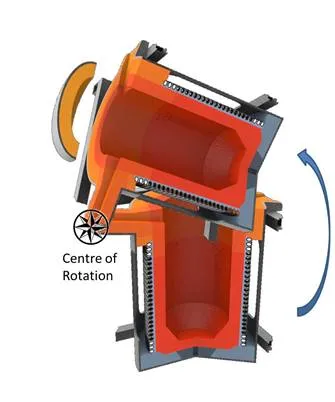

3. Hydraulic tilting. Furnace can rotate around the pouring spout, and tilting with proportional control, through controlling buttons of hydraulic station and the handle of tilting control device . Its tilting angle is vertically at 95 degrees and it can stay in any position in the process of rotating, as well as to change titling speed to more quicker or more slowly. It uses the manual valve operation and double machine double pump, with remote manual control system. Some other company only have single pump control. 4. Energy saving. The sensor is enclosed with a magnetic yoke, covering an area is over 65%, so the leakage is small and achieve the maximum electrical efficiency. Compared with aluminum shell furnaces, steel shell furnace can save nearly 5% power consumption.

4. Energy saving. The sensor is enclosed with a magnetic yoke, covering an area is over 65%, so the leakage is small and achieve the maximum electrical efficiency. Compared with aluminum shell furnaces, steel shell furnace can save nearly 5% power consumption.  Furnace

Furnace

Technical Parameter

| Furnace Capacity | Rating Power | Input Voltage | Pulse Count | Input Current | Assorted Transformer | Output Voltage | Melting Time |

| 50KG | 50KW | 380V | 6 | 80A | 60KVA | 750V | 20-45Min |

| 100KG | 100KW | 380V | 6 | 160A | 120KVA | 750V | 20-45Min |

| 150KG | 160KW | 380V | 6 | 256A | 200KVA | 750V | 20-45Min |

| 200KG | 160KW | 380V | 6 | 256A | 250KVA | 750V | 20-45Min |

| 250KG | 200KW | 380v | 6 | 320A | 315KVA | 750V | 20-45Min |

| 350KG | 250KW | 380V | 6 | 400A | 400KVA | 750V | 20-45Min |

| 500KG | 350KW | 380V | 6 | 560A | 500KVA | 750V | 30-50Min |

| 750KG | 500KW | 380V | 6 | 800A | 630KVA | 750V | 40-50Min |

| 1000KG | 750KW | 380V 750v | 6 | 1280A 656A | 1000KVA | 750V 990V | 40-50Min |

| 1500KG | 1000KW | 380V 750v | 6/12 | 800A 820A | 1250KVA | 750V 990V | 40-60Min |

| 2000KG | 1400KW | 750V 750V | 6/12 | 1148A 574A | 2000KVA | 990V | 45-60Min |

| 3000KG | 2000KW | 750v | 12 | 820A | 2500KVA | 990V | 50-70Min |

| 5000KG | 3000KW | 1000V | 12 | 1140A | 4000KVA | 1900V | 50-80Min |

Technical Support

1) Equipment designFurnace will be customized to meet your production needing and environmental condition (maximum ambient temperate, humidity, altitude,etc) .

2) Drawings delivery

Technical drawing will be send to the buyer after geting the deposite, so the buyer can build basic contruction before the furnace arrived.

3) Acceptance check before delivery

a. The supply of the inspection equipment complies with the scope of supply and technical specifications in the technical agreement.

b. Check the mechanical actions of the equipment.

c. Safety interlock of equipment and alarm function test.

4) Installation & debugging & worker training

a. Cooperate with guidance to check the buyer installation work;

b. Internal and electrical wiring connections between equipment;

c. Site commissioning;, according to the actual equipment adjust to the best state;

d. Direct buyer operating personnel to the correct use of operating equipment;

e. Guidance on site security considerations;

f. To guide the buyer maintenance personnel troubleshooting methods;

g. Provide equipment specification;

Advantages of Induction Melting Furnace

- Good power saving

- Simple operation and reliable operation

- Fast heating up

- Less smoke

- Temperature easy control

- Low surrounding temperature of furnace

- Compact structure and strong overload capacity

After Sale Service:

- 7 days training and debugging for free

- 3 year warranty

- Life time maintenance services

- 25 engineers to make sure the efficient after-sell

- Within 2 hours respond to the falut notification